End trucks are the transverse structures located at both ends of overhead crane bridges or gantry crane girders. They connect the main girders longitudinally, forming the crane’s rigid “I-beam” frame, and support the trolley travel mechanism for movement along tracks.

Main Frame: Typically a welded steel box-section (12-30mm plates) with stiffeners, providing high bending/torsional strength with optimal weight.

Travel Mechanism: Consists of drive wheels (usually hardened cast or forged steel), axles, bearings, and housings. Larger wheel diameters reduce ground pressure.

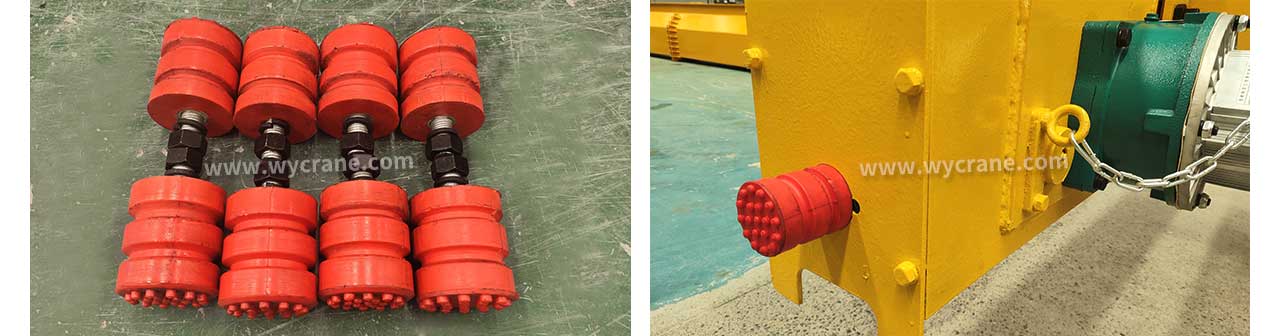

Buffers: Installed at both ends (common types: polyurethane, rubber, or hydraulic) to absorb impact energy at track ends.

Connection Points: Interfaces (high-strength bolted or welded) to securely join the end truck to the main girders.

Braking System: Spring-applied, electrically released brakes stop travel motion reliably.

Load Bearing: Transfers the crane’s total load (self-weight, hoist unit, lifted load) from the girders to the tracks. Designed with safety factors ≥1.5 and deflection limited to span/800.

Travel Stability: Wheel assemblies guide the crane precisely along tracks. Alignment is critical (parallelism ≤2mm/m, wheel verticality ≤1/1000).

Structural Connection: Forms the rigid end frame, integrating main girders and travel drives.

Impact Absorption: Buffers protect the crane and surrounding structures.

By Crane Type: Single-girder (lighter, for ≤10 tons), Double-girder (heavier, ≤50 tons), Underhung (compact wheels on I-beam flange).

By Wheel Arrangement: Two-wheel (common for medium loads), Four-wheel (halves wheel pressure without lengthening frame, ideal for capacity-limited structures).

By Construction: Fabricated box/welded (custom, heavy duty), Rectangular tube (lighter, less welding, cost-effective for medium loads ≤15t/span ≤25m).

Process: Cutting > Welding (CO2 gas shielded, GB/T3323-2005 Level II standard) > Machining (wheel mounting surfaces ≤0.1mm/m flatness) > Assembly (wheel diagonal tolerance ≤3mm) > Inspection.

Materials: Structural steels like Q235 (good weldability) or Q345 (higher strength).

Corrosion Protection: Blasted to Sa2.5, epoxy zinc primer, polyurethane topcoat.

Bolted: High-strength bolts (70% yield stress preload) connect flange plates; allows adjustment during installation.

Welded: Direct welded joint offers higher stiffness but increases residual stress risk and hinders replacement.

Hybrid: Combines welding in critical areas with bolting elsewhere (common for large cranes).

Optimize wheel pressure distribution (e.g., four-wheel setup halves pressure).

Balance light-weighting/material cost (e.g., tube sections save 15-20% weight) against performance limits.

Choose connection type considering rigidity, transport (bolted), and repairability.

Incorporate features for easier maintenance (e.g., self-lubricating wheels).

Robust buffers (polyurethane/rubber standard, hydraulic for heavy duty).

Anti-tip design: Low center of gravity, use of four-wheel setups, DC disc brakes.

Structural reinforcement: Stiffeners, gussets, and internal diaphragm plates prevent instability.

Daily: Visual inspection (structure, wheels, buffers, brakes), remove debris from wheels/tracks.

Periodic: Lubricate bearings/brake parts per schedule. Conduct weekly/monthly detailed checks.

Common Issues: Replace worn wheels, repair/straighten minor frame deformations, adjust/replace worn brake shoes, replace damaged buffers.

Prevention: Operator training, avoid shock loads/overloads, apply environmental protection as needed.

End trucks serve critical roles: transferring crane loads, ensuring stable movement along tracks, providing structural integrity at the girder ends, and absorbing impacts. They are essential for crane safety and function.

For more information, feel free to contact us! We are happy to provide advice and tailor solutions for you!

We have 34 years of manufacturing experience and 12 years of export experience,business covers over 100 countries and regions worldwide, including Asia, Europe, America, Africa, and Oceania, forming a global product sales network.Received ISO system certification and CE product certification!

Our main products include 6 series of nearly 100 varieties, including electric hoists, electric winches, gantry cranes, bridge cranes, marine cranes, and gantry cranes.

E-mail: karida@weiyinglift.com

Website: www.wycrane.com