An electric hoist is a compact, lightweight, yet powerful lifting device crucial in industrial production and logistics. It utilizes electric motors to lift and horizontally move loads, operating both independently or integrated into various cranes (overhead, gantry, jib). Widely used in factories, warehouses, and construction, capacities range from 0.1 to 80 tons(Customizable) with lifting heights of 3-30 meters.

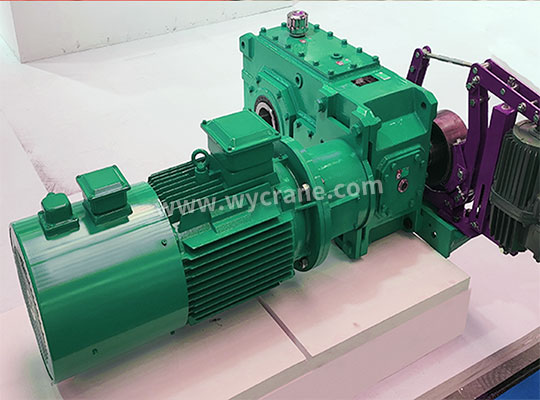

Drive Unit: Primarily electric motors (common types: conical rotor motors for inherent braking, or reliable squirrel cage motors).

Transmission: Gear systems (often hardened alloy steel in cast iron housings) transferring motor power to the lifting mechanism.

Lifting Mechanism: Contains the drum/wheels for wire rope/load chain, and a forged steel hook with safety latch.

Braking System: Essential safety feature, typically spring-applied, electrically-released brakes (e.g., disc or cone brakes) acting immediately on power loss. Mechanical brakes secure loads when stopped.

Control System: Electrical components (contactors, relays, buttons, limit switches, overload protectors) managing start/stop, direction, and safety functions.

By Drive: Electric (common, efficient) or Manual (no power required).

By Lifting Medium: Wire Rope Hoist (higher capacity/speed, e.g., CD single-speed, MD dual-speed for precision) or Chain Hoist (compact, low maintenance).

By Mobility: Fixed (lift only) or Traveling (lift and traverse on tracks).

Working Principle: Motor rotation is converted via the transmission into drum rotation. Winding/unwinding the rope/chain raises/lowers the hook. Traveling hoists have additional motors for horizontal movement. Brakes engage automatically when power is cut or movement stops.

Pre-Use Checks: Inspect hook, rope/chain, brakes, controls, and path/track.

Lifting: Perform a test lift (~10-20cm). Lift smoothly, avoid overloading, slanted pulls, or swinging loads. Never stand under a load.

Post-Use: Park correctly, raise hook, disconnect power, clean/inspect.

Daily: Clean, lubricate moving parts, perform visual inspections.

Scheduled: Monthly system checks; bi-annual brake service; annual motor maintenance. Replace worn parts promptly.

Safety Devices: Mandatory features include hook latches, overload limiters (cut power on overload), and lift/travel limit switches (prevent overtravel).

Personnel: Operators require proper safety training. Conduct regular equipment safety inspections.

Applications: Automotive assembly line part handling, precision semiconductor equipment placement, construction material lifting (steel, concrete), warehouse goods handling/logistics, power/utility maintenance (transformers), and shipbuilding.

Increases efficiency and safety, replacing manual handling. Enables precise 3D positioning of loads. Built-in safety mechanisms significantly reduce accident risks. Compact, versatile, and durable, it offers a cost-effective solution for lifting tasks compared to larger cranes.

The electric chain hoist is a fundamental, highly efficient, and adaptable lifting tool essential across numerous industries. Understanding its design, operation, maintenance, and safety protocols ensures reliable performance and harnesses its full potential.

For more information, feel free to contact us! We are happy to provide advice and tailor solutions for you!

We have 34 years of manufacturing experience and 12 years of export experience,business covers over 100 countries and regions worldwide, including Asia, Europe, America, Africa, and Oceania, forming a global product sales network.Received ISO system certification and CE product certification!

Our main products include 6 series of nearly 100 varieties, including electric hoists, electric winches, gantry cranes, bridge cranes, marine cranes, and gantry cranes.

E-mail: karida@weiyinglift.com

Website: www.wycrane.com