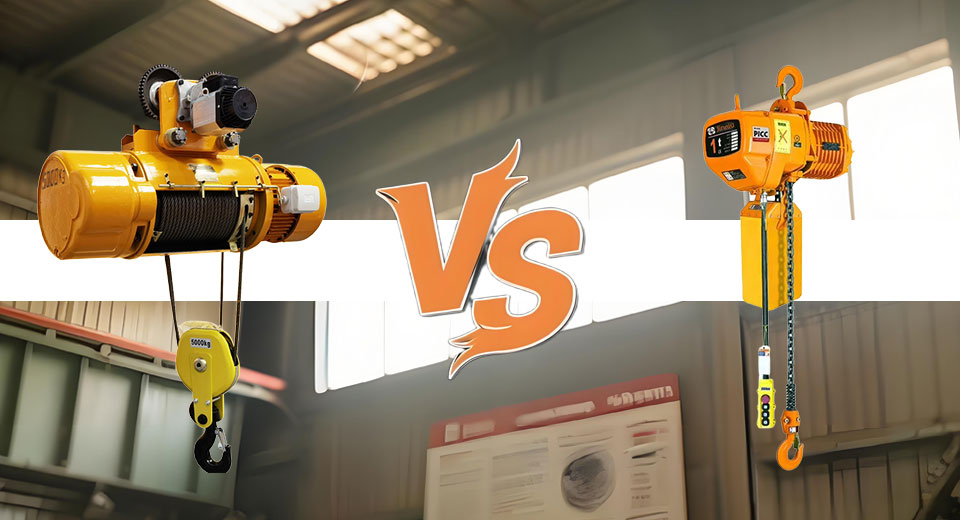

In industrial and construction settings, wire rope hoists and chain hoists are indispensable tools for lifting and moving heavy loads. While both serve similar purposes, their structural designs, performance characteristics, and application scenarios differ significantly. This article provides a detailed comparison of these two types of hoists, focusing on their core components, working principles, performance metrics, cost considerations, and ideal use cases. By understanding their distinctions, users can make informed decisions tailored to specific operational needs.

Wire Rope: Composed of multiple steel wire strands, known for high tensile strength and flexibility.

Drum: Winds and unwinds the wire rope to lift or lower loads.

Motor and Reducer: Provide power and control the speed of the drum.

Guide Pulleys: Ensure smooth movement of the wire rope.

The motor drives the drum to rotate, winding or unwinding the wire rope through the pulley system. The wire rope’s flexibility allows for long lifting heights (up to 100 meters) and adaptability to vertical or angled operations.

Load Chain: Constructed from high-strength alloy steel links, offering rigidity and wear resistance.

Sprocket and Gear System: Engages with the chain to transmit motion.

Hand Chain Wheel or Electric Motor: Manual or electric power sources.

The chain is pulled through a sprocket mechanism, lifting the load vertically. The rigid structure of the chain ensures precise positioning (±1 mm accuracy in manual mode) but limits lifting height (typically ≤20 meters). Chain hoists excel in confined spaces and frequent short-distance operations.

| Wire Rope Hoist | Chain Hoist | |

| Load Capacity | 0.25–100+ tons(customizable) | 0.25–20 tons(customizable) |

| Lifting Height | Up to 100 meters(customizable) | ≤20 meters(customizable) |

| Speed | 8–20 m/min (electric) | 1–8 m/min (electric) |

Wire Rope Hoist:High load capacity, long lifting height, fast speed, suitable for outdoor/harsh environments.

Chain Hoist:Compact design, precise control, low noise, easy maintenance, cost-effective.

Port container handling, mining equipment installation, and construction projects requiring loads exceeding 10 tons

Long-distance lifting, such as hoisting concrete panels to upper floors.

Withstands high temperatures (e.g., steel mills) and impact forces.

Electric models with variable frequency drives enable smooth starts/stops for delicate operations like precision instrument placement.

Warehouse logistics, workshop machinery maintenance, and assembly lines (e.g., automotive engine installation).

Mine tunnels, ship engine rooms, and areas with limited vertical clearance.

Ideal for power-free environments or emergency repairs using hand-pulled chains.

Initial Cost: Due to the presence of complex and precision components such as the drum and wire rope, the equipment purchase cost is relatively high.

Maintenance Key Points: Regularly inspect the wear and broken wire conditions on the surface of the wire rope. Lubricate and maintain the wire rope according to the specified cycle to ensure its stable performance and extend its service life.

Initial Cost: It is cost-effective. Especially for manual chain hoists, they have a great cost-performance advantage in scenarios with limited budgets.

Maintenance Key Points: Regularly check whether there are damages such as deformation and cracks in the chain. At the same time, lubricate the chain wheel to ensure the smooth operation of the equipment.

It adopts a dual braking system design, integrating the dual safeguard mechanisms of electromagnetic braking and mechanical braking. Even in sudden situations, it can achieve braking quickly and reliably, significantly improving the safety of equipment operation.

It is equipped with a self-locking chain wheel mechanism. When there is a power outage or power interruption, this mechanism is automatically triggered to firmly lock the load, effectively preventing the heavy object from falling and providing reliable safety protection for scenarios such as high-altitude operations.

Choose wire rope hoists for loads >10 tons or heights >20 meters.

Opt for chain hoists for loads <10 tons and limited spaces.

Wire rope hoists for outdoor/high-temperature settings (with rust-proofing).

Chain hoists for clean indoor areas or dust-prone environments.

Chain hoists for cost-sensitive, frequent short-cycle tasks.

Wire rope hoists for high-speed, heavy-duty operations.

Wire rope hoists and chain hoists cater to distinct operational demands. Wire rope hoists excel in heavy-load, high-speed, and long-height scenarios. Chain hoists, with their compact design and precision, are ideal for medium-light loads and confined spaces. Users must evaluate factors such as load requirements, environmental conditions, and budget constraints to select the optimal solution. By aligning equipment choice with specific needs, industries can enhance efficiency, reduce downtime, and achieve cost-effective outcomes.

For more information, feel free to contact us! We are happy to provide advice and tailor solutions for you!

We have 34 years of manufacturing experience and 12 years of export experience,business covers over 100 countries and regions worldwide, including Asia, Europe, America, Africa, and Oceania, forming a global product sales network.Received ISO system certification and CE product certification!

Our main products include 6 series of nearly 100 varieties, including electric hoists, electric winches, gantry cranes, bridge cranes, marine cranes, and gantry cranes.

E-mail: karida@weiyinglift.com

Website: www.wycrane.com