Looking for a versatile material handling solution? This guide covers free standing bridge cranes’ structure, key applications, unique benefits, and expert selection tips to help you make informed decisions for industrial needs.

|

|

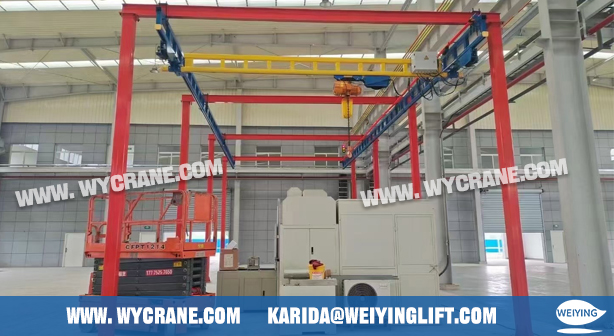

Bridge Beam: The main horizontal component that spans the work area, available in single girder or double girder designs. Single girder bridges are suitable for lighter loads, while double girder bridges handle heavier capacities.

End Trucks: Mounted at each end of the bridge beam, these units contain wheels that travel along the runways, enabling horizontal movement of the bridge.

Runway System: Consists of rails and support columns that provide the path for the end trucks. The support columns are anchored to the floor, eliminating the need for building attachments.

Hoist Mechanism: The lifting component that moves along the bridge beam, available as electric or manual hoists depending on the application needs.

Control System: Includes pendant controls, radio remote controls, or cabin controls for operating the crane, ensuring operator convenience and safety.

Independent Support Structure: Eliminates the need for building modifications, making installation faster and more cost-effective.

Modular Construction: Allows for easy expansion or reconfiguration as operational needs change.

High Load Capacity: Available in capacities ranging from small (1-5 tons) for light applications to heavy-duty (50+ tons) for industrial use.

Smooth Operation: Precision-engineered components ensure quiet, vibration-free movement, protecting both the crane and the loads being handled.

Safety Features: Equipped with overload protection, emergency stop buttons, limit switches, and anti-collision devices to ensure operator safety.

Automotive Production: Used for moving heavy components such as engines, chassis, and body parts along assembly lines.

Metal Fabrication: Handling steel plates, welded components, and finished products in fabrication shops.

Machinery Manufacturing: Assembling large equipment and moving heavy machine parts during production.

Material Storage: Lifting and positioning pallets, containers, and large storage items in warehouses.

Loading and Unloading: Efficiently moving goods between trucks, trains, and storage areas.

Inventory Management: Organizing heavy inventory items in high-density storage facilities.

Equipment Maintenance: Lifting and positioning large machinery for repair and maintenance work.

Vehicle Repair: Handling engines, transmissions, and other heavy components in automotive and truck repair shops.

Industrial Maintenance: Supporting maintenance activities in power plants, refineries, and other industrial facilities.

Aerospace Industry: Moving aircraft components and assemblies in manufacturing facilities.

Construction Sites: Temporary installation for lifting materials in large construction projects.

Shipyards: Handling ship components and materials in marine manufacturing facilities.

Can be installed in any location with a suitable floor foundation, regardless of building structure.

Easy to reconfigure or relocate as business needs change, providing long-term value.

Accommodates various load sizes and weights, from small parts to heavy industrial components.

Eliminates the need for expensive building modifications or structural reinforcements.

Lower installation costs compared to building-supported cranes, as no overhead structural work is required.

Reduces long-term maintenance costs due to the modular design and easy access to components.

Maximizes floor space utilization by keeping the work area clear of permanent structures.

Allows for full use of the overhead space, enabling higher storage and handling capacity.

Can be designed to fit specific space requirements, from small workshops to large industrial facilities.

Equipped with advanced safety features to protect operators and prevent accidents.

Stable and secure operation due to the robust support structure and precision engineering.

Complies with international safety standards, ensuring safe operation in all industrial environments.

Enables faster and more efficient material handling, reducing production downtime.

Easy to operate, requiring minimal training for operators to achieve optimal performance.

Can be integrated with other material handling systems for seamless operation throughout the facility.

Small Capacity: 1-5 tons, suitable for light manufacturing and maintenance applications.

Medium Capacity: 5-20 tons, ideal for general manufacturing and warehousing operations.

Heavy Capacity: 20-50 tons, designed for heavy industrial applications and large component handling.

Extra-Heavy Capacity: 50+ tons, specialized for extreme industrial use in sectors like steel production and shipbuilding.

Typically ranges from 10 feet to 100 feet, depending on the facility dimensions and application needs.

Custom span lengths available to fit specific facility requirements.

Longer spans may require double girder designs for added stability.

Standard lifting heights range from 10 feet to 50 feet.

Custom lifting heights available for specialized applications.

Affected by the crane design and the available vertical space in the facility.

Bridge Travel Speed: 50-200 feet per minute, adjustable based on load size and application needs.

Hoist Lifting Speed: 10-60 feet per minute, with variable speed options for precise handling.

Trolley Travel Speed: 30-150 feet per minute, ensuring efficient load positioning.

Electric-powered models typically require 220V, 380V, or 480V three-phase power.

Some models available with dual-voltage options for international use.

Energy-efficient designs available to reduce power consumption and operating costs.

Pendant Controls: Handheld controls for operators working near the crane.

Radio Remote Controls: Allows operators to control the crane from a safe distance.

Cabin Controls: Enclosed operator cabins for large cranes requiring continuous operation.

Operating in a rented facility where building modifications are not allowed

Needing flexibility to reconfigure or relocate the crane in the future

Working with existing buildings that lack suitable overhead support structures

Requiring a crane solution with faster installation and lower initial costs

Constructing a new facility where overhead support can be integrated into the design

Having specific weight capacity requirements that align with the building structure

Needing to maximize floor space utilization

Planning for a permanent crane installation with no future relocation needs

Determine the maximum load weight you need to handle, including any potential future increases.

Identify the typical load dimensions (length, width, height) to ensure proper crane sizing.

Evaluate the required lifting height and horizontal coverage area.

Measure the available floor space and ceiling height to determine suitable crane dimensions.

Assess floor conditions to ensure they can support the crane’s weight and load requirements.

Consider environmental factors such as temperature, humidity, and potential exposure to corrosive substances.

Girder Type: Choose between single girder (lighter loads, lower cost) or double girder (heavier loads, higher stability) designs.

Hoist Type: Select electric hoists for heavy-duty, frequent use or manual hoists for light, occasional use.

Control System: Decide on pendant, radio remote, or cabin controls based on operator safety and convenience needs.

Ensure the crane meets international safety standards (OSHA, ISO, etc.) for your industry.

Look for essential safety features such as overload protection, emergency stops, and limit switches.

Consider additional safety options like anti-collision systems and load monitoring devices for high-risk applications.

Choose a reputable supplier with experience in designing and manufacturing free standing bridge cranes.

Check for comprehensive after-sales support, including installation, maintenance, and repair services.

Inquire about warranty coverage and availability of replacement parts for long-term reliability.

Develop a detailed installation plan that minimizes disruption to your operations.

Establish a regular maintenance schedule to ensure optimal crane performance and longevity.

Train operators properly to ensure safe and efficient crane operation.

With 34 years of manufacturing experience and 12 years of export expertise, we have built a dual advantage of professional qualifications and a global presence. Our business covers more than 100 countries and regions across Asia, Europe, the Americas, Africa, and Oceania. We are certified under the ISO management system and hold CE product certifications. Our main product lines include six major series—electric hoists, electric winches, gantry cranes, bridge cranes, marine cranes, and portal cranes—comprising nearly 100 different models.

If you want to learn more, please contact us.

E-mail address: karida@weiyinglift.com

Website: www.wycrane.com