Freestanding jib cranes are among the most efficient and versatile lifting systems used across modern manufacturing, logistics, and maintenance operations. Their compact structure, 360-degree rotation, and independent installation make them ideal for localized material handling—especially in workshops, assembly lines, and small workstations.

However, despite their simple design, many operators still make critical mistakes that can shorten equipment life or lead to safety hazards. Most issues arise not from poor manufacturing, but from improper installation, misuse, or insufficient maintenance.

This article explains the most common mistakes made when using freestanding jib cranes and provides practical tips to help you ensure safety, stability, and long-lasting performance.

|

|

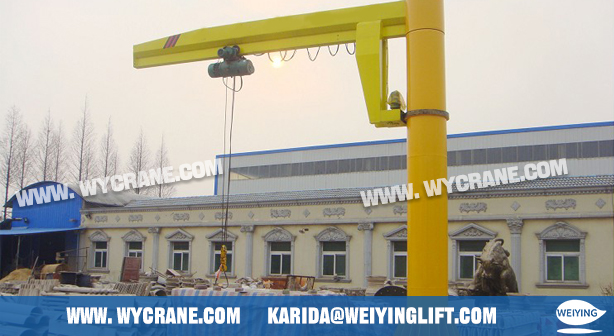

Freestanding jib cranes—also known as floor-mounted pillar jib cranes—are designed to operate as self-supporting lifting systems that don’t depend on walls or building structures. One of the most popular models in this category is the BZ Type Floor Mounted Pillar Jib Crane, known for its strong performance and flexible configuration.

The BZ jib crane typically offers:

Load capacity: up to 10 tons

Working span: up to 12 meters

Cross-travel speed: up to 20 meters per minute

Lifting speed: up to 8 meters per minute

Working class: A3, suitable for regular industrial duty cycles

This design allows for 360° rotation around its pillar, enabling the operator to lift, rotate, and position loads precisely within its working radius. Because it’s mounted on a concrete foundation, it provides stable operation even under continuous use.

BZ jib cranes are widely applied in machinery workshops, maintenance bays, warehouses, ports, and outdoor loading areas. Their robust design ensures reliable performance, but to achieve their full potential, correct installation and operation are essential.

Even high-quality cranes like the BZ type can suffer premature wear or operational issues if misused. Below are the seven most common mistakes users should avoid:

The foundation is the most critical structural component for a freestanding jib crane. A weak or incorrectly designed base can cause the entire column to tilt, vibrate, or even fail under load.

Typical errors include:

Installing the crane on insufficiently thick concrete flooring

Improperly embedded anchor bolts

Skipping the foundation curing time before use

How to avoid it:

Follow the manufacturer’s foundation design drawings for depth and reinforcement.

Use certified installers familiar with BZ-type base anchoring.

Always conduct a load test after installation to verify structural integrity.

Every crane has a defined safe working load, and exceeding it—even slightly—can permanently deform the jib arm, overload the slewing bearing, or damage the hoist.

Example:

A BZ jib crane with a 10-ton rating should never be used to lift a 12-ton load “just once.” The structural stress may not cause immediate failure, but it weakens the steel over time.

Prevention tips:

Always confirm the weight of the load before lifting.

Avoid shock loading (sudden jerks when lifting or stopping).

Install load limiters to prevent accidental overloads.

Jib cranes are designed for vertical lifting only. Pulling the load sideways introduces horizontal forces that the structure isn’t designed to resist, potentially causing bending, twisting, or bearing damage.

How to prevent side pulling:

Keep the hoist hook directly above the load center before lifting.

Use the jib’s rotation motion instead of the hoist to reposition the load.

Train operators to recognize the dangers of angled lifting.

The simplicity of a jib crane can lead to complacency—many operators assume “no maintenance is needed.” In reality, regular inspections are crucial to prevent wear and mechanical failure.

Neglected areas include:

Bearings and slewing gear lubrication

Wire rope inspection

Hoist brakes and limit switches

Electrical wiring and control buttons

Maintenance recommendations:

Perform daily visual checks before each shift.

Lubricate rotating parts monthly.

Conduct a comprehensive inspection every 6 months by certified technicians.

BZ-type freestanding jib cranes can operate indoors or outdoors, but the surrounding environment has a major impact on durability and safety.

Common problems:

Corrosion in coastal or humid regions

Wind-induced rotation in outdoor setups

Temperature fluctuations affecting lubrication

Best practices:

Use anti-corrosion coatings or galvanized structures for outdoor cranes.

Install wind locks or rotation limiters in high-wind areas.

Select low-temperature grease and weatherproof electrical enclosures for cold climates.

Even the best-engineered crane can be unsafe in unskilled hands. Untrained operators are more likely to overload, side pull, or ignore early warning signs like unusual noise or vibration.

Solutions:

Conduct formal operator training before commissioning.

Establish a supervision system with certified crane personnel.

Encourage operators to report issues immediately rather than “making do.”

Altering the crane structure—such as extending the jib arm, replacing the hoist with a different model, or rewiring the control system—without manufacturer approval can seriously compromise safety.

Why it matters:

Each BZ jib crane is designed with a specific balance between the column, boom, and base. Unauthorized modifications disrupt that balance, leading to mechanical instability or failure.

How to avoid it:

Only use original manufacturer-approved spare parts.

Request an engineering review before making any structural or electrical changes.

Avoid “DIY” repairs on load-bearing parts.

To ensure your freestanding jib crane delivers long-term performance:

Conduct pre-operation checks (bolts, cables, brakes, and electrical systems).

Keep the work area clear of obstacles and personnel during operation.

Install safety features like overload limiters, emergency stops, and anti-sway controls.

Document all maintenance and inspection activities.

Follow the A3 working class duty rating to avoid excessive use.

When used correctly, a BZ-type floor-mounted jib crane can operate smoothly for 15 to 20 years or more. Proper care ensures:

Fewer breakdowns and lower maintenance costs

Consistent performance under rated loads

Extended service life of up to 30% longer

Safer working conditions for operators

By investing in proper installation, maintenance, and operator training, you not only protect your equipment but also boost workplace efficiency and safety.

Freestanding jib cranes—especially BZ Type Floor Mounted Pillar Jib Cranes—offer unmatched versatility and strength for localized lifting tasks.

But their long-term reliability depends on proper foundation, operation, and care.

Avoiding common mistakes such as overloading, side pulling, and ignoring maintenance is the simplest way to keep your crane safe, stable, and productive for years to come.

With 34 years of manufacturing experience and 12 years of export expertise, we have built a dual advantage of professional qualifications and a global presence. Our business covers more than 100 countries and regions across Asia, Europe, the Americas, Africa, and Oceania. We are certified under the ISO management system and hold CE product certifications. Our main product lines include six major series—electric hoists, electric winches, gantry cranes, bridge cranes, marine cranes, and portal cranes—comprising nearly 100 different models.

If you want to learn more, please contact us.

E-mail address: karida@weiyinglift.com

Website: www.wycrane.com