|

|

A bridge crane kit is a complete package of mechanical, electrical, and control components used to assemble an overhead crane system. Instead of purchasing parts separately—which often leads to incompatibility, increased installation time, and complex engineering—customers receive a full solution engineered to work together seamlessly.

A standard bridge crane kit includes:

End beams / end trucks

Hoist and trolley unit

Control system (pendant, remote, or cabin)

Electrical system (power supply + main panel)

Optional safety devices and smart features

VFD drives, dual-speed motors, adaptive frequency control

These components are universally applied in single girder overhead cranes and double girder overhead cranes, ensuring smooth operation, high stability, and long service life.

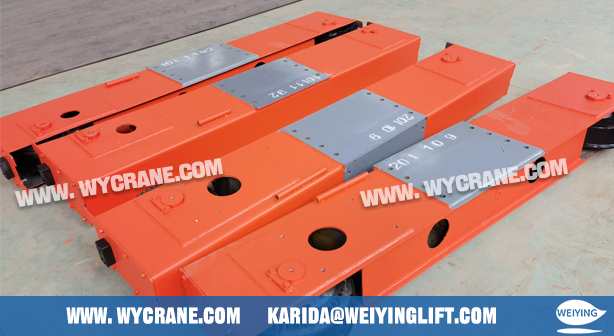

End beams—also known as end trucks—are essential for supporting and guiding the movement of the entire overhead crane along the runway. They are often manufactured from high-strength steel with CNC-machined wheel groups to ensure excellent precision and durability.

Key characteristics:

Heavy-duty wheels with hardened tread for long service life

Motorized or manual travel options

Reduced vibration and noise during long-distance travel

Gearbox and motor integrated design for stable bridge movement

In many industrial settings, the end trucks are responsible for carrying thousands of travel cycles each year; therefore, their quality directly determines the long-term performance of the entire overhead crane system.

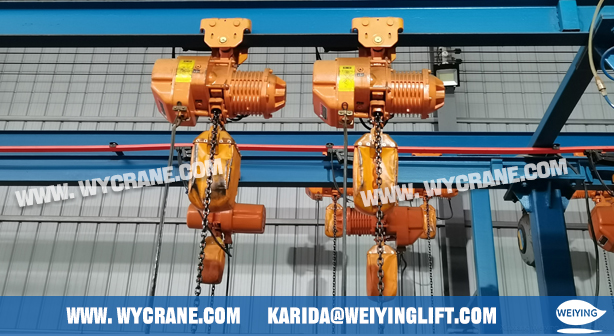

The hoist and trolley is the core lifting component within a bridge crane kit. It determines the lifting capacity, lifting speed, and reliability of your overhead crane.

Common types include:

Electric Wire Rope Hoist for medium to heavy-duty lifting

Electric Chain Hoist for light to medium-duty applications

Open winch hoist for heavy-duty double girder cranes

The trolley runs on the crane girder and controls the horizontal movement of the hoist. Modern hoist-trolley units are engineered with:

Precision gearboxes

Efficient motors

Rope guides and limiters

High-strength hooks

Thermal protection for motors and electronic components

Integrating the hoist and trolley into the crane kit ensures complete compatibility with end beams, power systems, and control components.

A reliable crane control system ensures smooth and accurate operation of your bridge crane kit. Options typically include:

Pendant control

Wireless radio remote control

Operator cabin control (mainly for heavy-duty double girder cranes)

Modern control systems feature intelligent logic functions, allowing precise control of lifting, trolley travel, and bridge travel. For example:

Soft-start operation

High-accuracy load positioning

Programmable limits

Anti-sway technology

VFD integration for smooth speed adjustment

With an optimized control system, operators benefit from improved safety, reduced fatigue, and easier handling of loads with irregular shapes or sensitive surfaces.

The electrical system powers and coordinates all crane movements. A standardized electrical system within the bridge crane kit ensures maximum reliability.

Typical electrical components include:

Main power distribution panel

Contactors, relays, overload protection, MCCB

Energy supply systems: festoon cable or conductor bar system

Limit switches for end travel and lifting limits

Control cables and safety wiring

A high-quality electrical system significantly reduces downtime caused by wiring failures, overload trips, or signal interruption.

Safety is a core advantage of using a well-engineered bridge crane kit. To meet international standards (ISO, FEM, CMAA), various safety devices can be integrated:

This electronic system reduces or eliminates load swaying during acceleration, deceleration, or sudden stops. It improves load positioning accuracy and is highly beneficial in:

Precision assembly workshops

Steel coil or mold handling

High-speed crane travel environments

LED indicators, buzzers, and warning sirens alert workers during crane operations, increasing workplace safety.

An automatic device that prevents lifting beyond rated capacity, protecting both operators and machinery.

Installed for:

Upper and lower hook travel

Trolley travel limits

Bridge end stop protection

These safety devices ensure the crane operates within safe boundaries at all times.

Modern bridge crane kits increasingly incorporate advanced motor control technologies that improve efficiency and safety.

Provide two operation speeds:

Low speed for precise positioning

High speed for general lifting and fast workflow

A VFD greatly enhances crane performance by controlling motor frequency and voltage. Benefits include:

Smooth acceleration and deceleration

Extended motor and gearbox lifespan

Precise load handling

Reduced hook sway

Lower energy consumption

This advanced system automatically adjusts operation speed based on load weight and movement distance, offering the most efficient handling in dynamic working conditions.

Bridge crane kits are available for two mainstream structural types:

Best for:

Light and medium-duty applications

Workshops with low headroom

Facilities requiring cost-effective solutions

Advantages include:

Lightweight construction

Simple installation

Lower procurement cost

Excellent compatibility with electric hoists

Best for:

Heavy-duty lifting

High lifting heights

Long spans or continuous operations

Advantages include:

Greater lifting capacity

Higher rigidity

Space for maintenance platforms

Compatibility with heavy-duty hoist trolleys

Both crane types benefit from the same standardized components in the bridge crane kit, ensuring easy assembly and maintenance.

A well-engineered bridge crane kit is the optimal solution for industries that require efficient, safe, and reliable overhead lifting systems. With standardized end beams, hoist-trolley units, control systems, electrical systems, advanced VFD drives, and modern safety features, these kits ensure seamless assembly, long-term performance, and exceptional customization flexibility.

With 34 years of manufacturing experience and 12 years of export expertise, we have built a dual advantage of professional qualifications and a global presence. Our business covers more than 100 countries and regions across Asia, Europe, the Americas, Africa, and Oceania. We are certified under the ISO management system and hold CE product certifications. Our main product lines include six major series—electric hoists, electric winches, gantry cranes, bridge cranes, marine cranes, and portal cranes—comprising nearly 100 different models.

If you want to learn more, please contact us.

E-mail address: karida@weiyinglift.com

Website: www.wycrane.com

2.Shop Overhead Crane: How to Choose the Right Crane for Your Workshop

3.Electric Chain Hoist: Revolutionizing Heavy Load Handling in Confined Spaces

4.Some little knowledge about end beams

5.What is the difference between a hydraulic winch and an electric winch?