The circuit breaker is a core safety protection device in the electric control box. When a hazardous fault occurs in the circuit, it quickly cuts off the power supply to prevent equipment damage or safety accidents (such as fire and electric shock).

It is the core executive component that connects the commands of the wireless remote control and the high-power main circuit of the crane. In essence, it serves as a “power switch hub” that receives signals from the wireless remote control and realizes the “controlled on-off” of the crane’s main circuit.

The phase sequence protector is a safety protection device in three-phase AC circuits that ensures the normal phase sequence and voltage of the power supply. Its core function is to detect the phase sequence, phase loss, and voltage stability of the three-phase power supply. When the power supply is abnormal, it cuts off the circuit to prevent equipment damage, misoperation, and safety accidents.

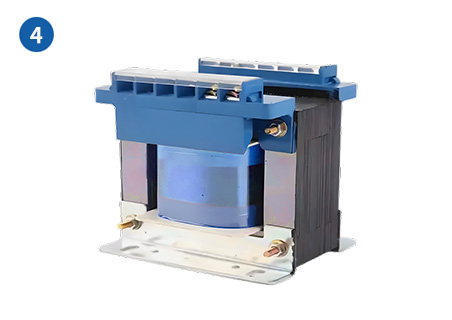

It is the core conversion device that connects the high-voltage main power supply and the low-voltage control circuit. Its functions include: reducing voltage to prevent burnout of control components; providing electrical isolation to prevent leakage interference, electric shock, and misoperation; and stabilizing voltage to avoid crane control failure caused by fluctuations in the main power supply.

The automatic contactor is a core executive component for the motors of specific mechanisms in the crane’s electric control box. Its functions are: receiving signals to switch the motor’s main circuit on or off to realize start and stop; changing the phase sequence to control forward and reverse rotation (e.g., hoisting/lowering); and disconnecting under voltage loss to prevent accidents caused by unexpected power recovery.

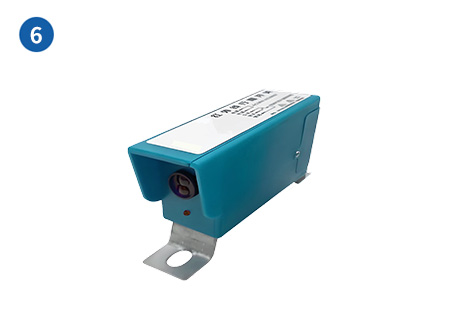

Its core function is to detect obstacles in the crane’s operating path using non-contact infrared detection technology. When the distance to an obstacle is less than the safe range, it issues an early warning; if the warning is ineffective, it controls the corresponding mechanism to emergency stop or decelerate to avoid collisions.

The cross limit switch is a core safety protection device for cranes. It restricts the maximum travel of vertical lifting and horizontal movement, forcibly stops over-travel actions, and thus prevents safety accidents.

Differences between the infrared anti-collision switch and the cross limit switch

The cross limit switch uses a mechanical travel switch to monitor whether the crane itself has reached the preset maximum physical position, and cuts off the power to prevent over-travel. In contrast, the infrared anti-collision switch adopts non-contact infrared detection to sense the distance between the crane and surrounding obstacles; when an obstacle enters the set safety range, it triggers an alarm or shuts down the machine immediately.

Its core functions are: realizing stepless speed regulation of crane mechanisms (such as hoisting and traveling) by adjusting the motor power supply frequency; achieving soft start/soft stop to reduce mechanical impact; saving energy dynamically based on load; and providing overload protection as well as coordinating the synchronous operation of multiple mechanisms.

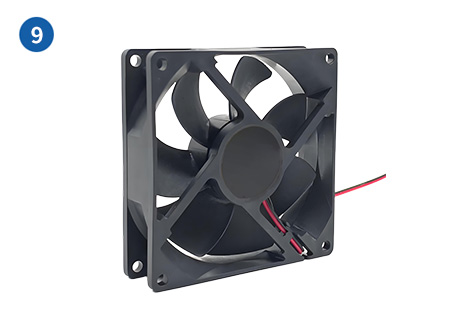

Its core role is to provide forced cooling for high-power, high-heat-generating electrical components inside the electric control box. It dissipates the heat generated by the components during operation through air flow, preventing component performance degradation, service life reduction, or even burnout due to excessive temperature.

The acoustic-optical alarm is one of the core safety devices for ensuring personnel safety, equipment safety, and operational coordination. Its core role is to transmit key information through dual signals of “sound warning” and “light warning” in complex operating scenarios, helping to avoid risks in advance.

Whether it is heavy lifting in factory workshops, cargo handling in logistics parks, or high-altitude operations at construction sites, the stability of the crane’s electrical control box directly determines the operation efficiency and safety threshold. If you need to learn more about the specific parameters or compatible crane models of a certain accessory, or want to obtain details of customized solutions, please feel free to contact us at any time. Our technical team will connect with you as soon as possible and develop a cost-effective solution for you.

We have 34 years of manufacturing experience and 12 years of export experience,business covers over 100 countries and regions worldwide, including Asia, Europe, America, Africa, and Oceania, forming a global product sales network.Received ISO system certification and CE product certification!

Our main products include 6 series of nearly 100 varieties, including electric hoists, electric winches, gantry cranes, bridge cranes, port cranes, and jib cranes.

E-mail: karida@weiyinglift.com

Website: www.wycrane.com