Switching your crane from wired to radio remote control can immediately make your operations safer, faster, and more efficient. With wireless control, operators gain the freedom to move, a clearer view of the load, and better overall control — all of which translate into higher productivity and fewer accidents.

In today’s fast-paced industrial world, efficiency, safety, and flexibility are the driving forces behind profitability. Cranes are at the center of most material-handling processes, but how they are controlled can make all the difference.

Here are five key reasons why investing in radio remote control for your crane is one of the smartest upgrades you can make.

Safety is always the top priority in any lifting operation. One of the biggest advantages of radio remote control is that it keeps the operator at a safe distance from the load.

Instead of standing directly beneath or near a moving hook, the operator can position themselves at a secure location with a clear view of the lifting area. This drastically reduces the risk of injury caused by load swing, collision, or falling objects.

In addition, wireless control gives the operator a better line of sight, allowing them to monitor the load path more accurately and ensure that no one enters dangerous zones. By separating the human from the hazard, radio control significantly improves both personal and workplace safety — a crucial factor in industries such as steel manufacturing, logistics, construction, and heavy machinery.

|

|

Radio remote control doesn’t just make crane operations safer — it also makes them faster. When using a pendant cable, operators are physically tied to the crane, often navigating around obstacles or untangling cords that restrict movement.

With radio control, these limitations disappear. Operators can move freely across the workspace, position themselves for optimal control, and complete lifting tasks more smoothly and efficiently.

Another key productivity advantage is multi-tasking capability. In many cases, an operator can manage rigging or positioning tasks while controlling the crane at the same time. This eliminates the need for a second operator and allows for faster load handling cycles.

Over time, this improvement in workflow adds up to significant time savings and reduced labor costs, giving your operation a measurable boost in productivity.

Every workspace has unique challenges — tight spaces, obstacles, varying visibility, or complex lifting paths. Radio remote control provides operators with the flexibility to move wherever they need to be to handle these challenges effectively.

With a handheld transmitter, the operator can position themselves at the best possible angle to see the load and surrounding area. This improved vantage point allows for more precise load positioning, especially when navigating around obstacles or placing loads in confined spaces.

This mobility also enhances communication and coordination with other team members. Operators can stay close to riggers or signalers, ensuring better teamwork and fewer misunderstandings.

In short, wireless control empowers operators to adapt to their environment instead of being restricted by cables — leading to smoother, safer, and more confident crane operation.

Cable-controlled cranes are prone to one common issue: cable damage. Pendant control cables can become twisted, caught, or worn over time — especially in harsh industrial environments. When that happens, operations often need to stop for repair or replacement.

By switching to radio control, you eliminate the physical cable connection altogether. This means no downtime due to cable failure, fewer maintenance tasks, and less disruption to production.

Modern radio systems are built to withstand tough conditions, including dust, heat, vibration, and moisture. Their reliability and durability make them ideal for heavy-duty applications where uptime is critical.

In addition, radio control simplifies installation and system upgrades. With fewer physical components and less wiring, maintenance teams spend less time troubleshooting and more time keeping operations running smoothly.

Operating a crane via pendant control often requires repetitive arm and wrist movements while managing a heavy, hanging controller. Over time, this can lead to physical strain and operator fatigue — especially during long shifts.

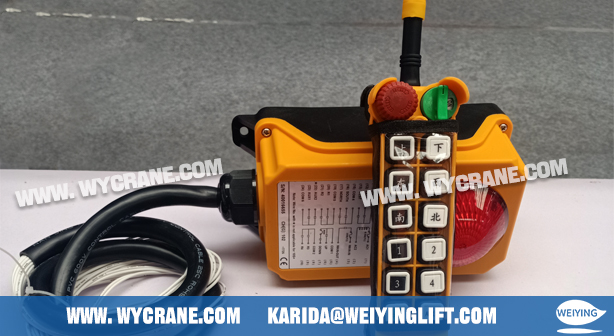

Radio remote controls are designed with ergonomics in mind. They are lightweight, comfortable to hold, and equipped with intuitive push buttons or joysticks that reduce physical effort.Because operators can work from a relaxed, safe position without constantly adjusting cables or bending awkwardly to follow the crane’s path, they experience less stress and greater comfort.

This improvement in ergonomics leads to higher concentration, fewer mistakes, and a more sustainable work rhythm — all of which contribute to long-term safety and performance.

Transitioning your crane to radio remote control is not just a technological upgrade — it’s a strategic investment in operational safety, efficiency, and employee well-being.

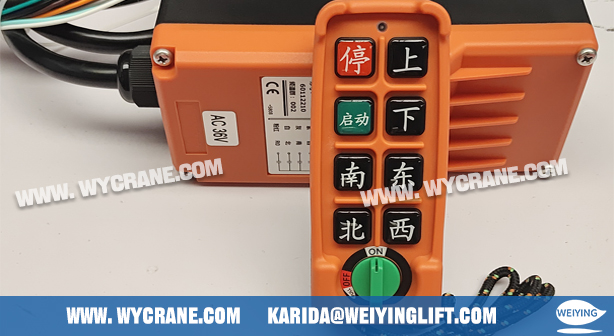

With rapid advancements in industrial automation, radio control systems now offer features like digital signal encryption, battery-life monitoring, two-way feedback, and emergency-stop synchronization. These innovations make them even safer and more dependable than before.

Whether you operate an overhead crane, gantry crane, jib crane, or hoist system, radio control can be easily integrated into your existing setup with minimal downtime. It’s a proven way to modernize your lifting operations while keeping costs under control.

Switching your crane from pendant to radio remote control delivers real-world benefits across every aspect of your operation: safer work environments, faster workflows, fewer interruptions, and happier operators.

In a competitive industrial landscape, these advantages translate directly into higher productivity, lower costs, and improved business performance.

With 34 years of manufacturing experience and 12 years of export expertise, we have built a dual advantage of professional qualifications and a global presence. Our business covers more than 100 countries and regions across Asia, Europe, the Americas, Africa, and Oceania. We are certified under the ISO management system and hold CE product certifications. Our main product lines include six major series—electric hoists, electric winches, gantry cranes, bridge cranes, marine cranes, and portal cranes—comprising nearly 100 different models.

If you want to learn more, please contact us.

E-mail address: karida@weiyinglift.com

Website: www.wycrane.com