In the field of industrial production, single beam cranes, as a common material handling equipment, play a key role in improving production efficiency and reducing physical labor intensity. With the development of technology, European single beam cranes have gradually emerged, forming a clear contrast with traditional ordinary single beam cranes. Below, a detailed analysis will be conducted from various aspects such as design concepts, structural characteristics, manufacturing processes, performance, applicable scenarios, and costs, to help you gain a deeper understanding of the differences between the two and make appropriate choices based on actual needs.

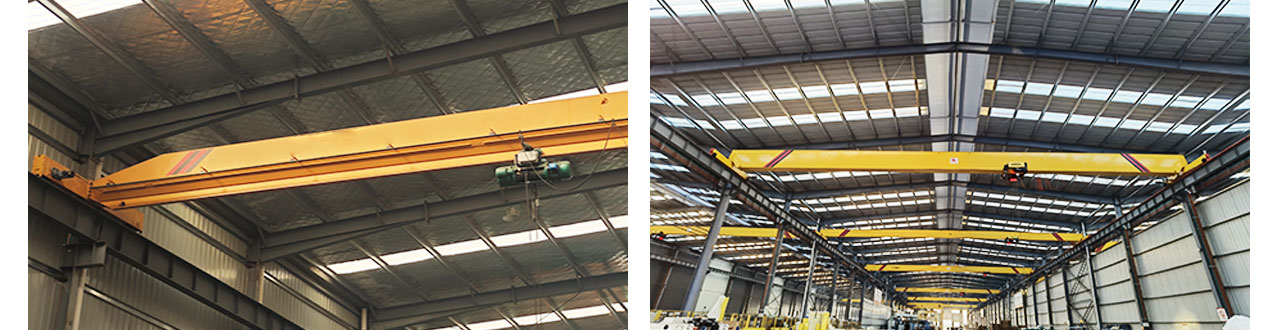

The European single beam crane adheres to advanced design concepts and strictly follows the European Union’s EN13001 series standards for crane design. With precise calculation as the core and advanced technologies such as finite element analysis to optimize material distribution, we aim to achieve a high degree of fit between the overall force model and structural design, pursuing comprehensive optimization goals of safety, reliability, efficiency, and energy conservation. Our structure is compact and the stress distribution of components is balanced. For example, a 10 ton European style single beam crane customized for a large equipment assembly workshop has a total height of only 1.6 meters, successfully solving the problem of height limitation in the factory building, while also exhibiting good load-bearing stability and motor temperature rise performance.

In contrast, ordinary single girder cranes mainly follow national standards such as GB/T 3811-2008 “Design Specification for Cranes” and JB/T 1306-2008 “Electric Single girder Cranes” in China. There are many empirical parameters in early design. Manufacturers often design and manufacture based on the lower limit of standards, focusing on meeting basic functional requirements while considering manufacturing costs, resulting in a high degree of redundancy in the overall structural strength of the equipment and a heavy weight.

The main beam of the European style single beam crane is mainly an I-shaped structure, which is made of high-quality steel plates (such as Q345B or higher strength materials) and precision formed by fully automatic welding technology. Its cross-section is efficient, the flange width is large, and the web height is accurately calculated to form a reasonable bending section; Lightweight and high-strength, the material thickness is thin but the strength is high under the same lifting capacity, and the self weight is 15% -40% lower than that of similar ordinary single beam cranes; The upper arch is fine, and the preset arch degree is controlled within 1/1000 of the span L, effectively offsetting heavy load deformation and ensuring smooth operation.

The main beam of ordinary single beam cranes is mostly a “U” – shaped channel steel welded structure or a combination structure of “I-beam+enclosed cover plate”. The design process of adding cover plates to I-beams is complex, and the overall weight is significantly higher than that of European I-beams; The preset arch value range is between 1/1000 and 1/500 of the span L.

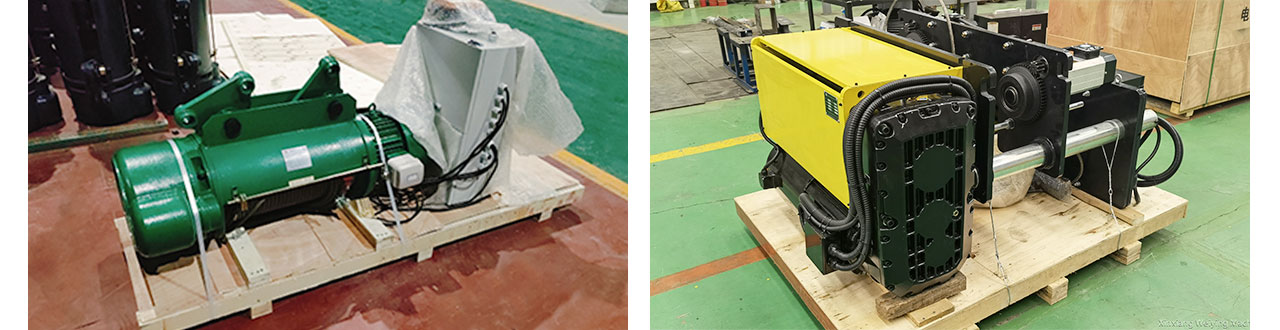

The lifting mechanism of European cranes is equipped with high-efficiency motors (IE3 or higher energy efficiency level), and the reducer adopts hard tooth surface gear technology, which is treated with carburizing and quenching, and is mostly a three in one drive unit (motor, reducer, brake highly integrated design). The diameter of the drum has been carefully calculated, and the steel wire rope is wound smoothly with low risk of fatigue damage. High flexibility and specific coating steel wire ropes are usually used. The braking system is mandatory to be equipped with dual independent brakes, and the braking safety factor strictly follows the EN standard requirements (≥ 1.75).

The lifting mechanism of ordinary single beam cranes often uses ordinary three-phase asynchronous motors, and the gear of the reducer is surface quenched, which is mostly a multi-component assembly structure. The diameter design of the drum meets the standard requirements, and the brake is usually equipped with a single drum or disc brake at the motor extension end.

The drive system designed in European style is highly integrated (often in a three in one structure) and equipped with a high-frequency conical rotor motor. The wheel material is high-strength alloy forgings or ductile iron, and the wheel pressure is strictly calculated to maintain a reasonable lower limit. The bearings are excellent, the running resistance is small, the driving force coefficient is low, and the wheel rim shape has good buffering effect on the lateral force of the track.

Ordinary design drive systems are mostly separated layouts (motors, brakes, and reducers are connected through couplings after separation), wheels are mostly made of cast steel, and bearings are universal products.

European design usually adopts a decentralized drive form, introducing a synchronous control system (frequency conversion speed regulation combined with electronic differential compensation) between the dual side drive units to reduce rail gnawing phenomenon, and achieve smooth and impact free acceleration during start-up and operation.

Ordinary designs often adopt centralized drive or edge combination drive methods, and the speed regulation forms are mostly variable pole speed regulation or simple start stop control relying on fixed speed motors.

The European standard variable frequency speed regulation technology is widely used in lifting and trolley drive, achieving light and slow load starting and precise positioning. The system is equipped with multiple fault self diagnostic sensors, using a safe voltage control circuit, with high protection level and strong resistance to water vapor and dust erosion.

Conventional systems based on contactor combinations are commonly used, with speed regulation relying on variable pole motors or multiple gears in conjunction with conventional drives. The protection circuit mainly includes load limiters, phase failure protection, and other items. The protection level of the control box is usually IP44, and its protection ability is insufficient in harsh environments.

European design has significant advantages in space utilization. The height of the main beam (H2) is 15% -25% lower than that of ordinary models under the same working conditions due to the optimized I-beam section and compact three in one drive technology. The wheelbase (W) is more compact due to optimized horizontal rigidity design and diversified driving forms, and the upper limit position (Cmin) can be optimized to a higher level by relying on a thinner drum structure and hook group configuration. This allows European style cranes to reduce the height of factory structures and save construction costs in new construction planning; In the renovation project, the originally restricted factory buildings can be used for equipment addition to improve space utilization.

The European single beam crane follows strict safety regulations and has a dual safety design, such as dual brakes, anti slip groove protection device for the lifting pulley system, anti rotation positioning structure for the hook, and large vehicle rail sweeper. The EN13001 standard proposes rigorous fatigue calculation requirements based on finite life for the entire machine and key load-bearing components.

The safety benchmark of ordinary single beams is mainly reflected in strength design and basic safety device coverage, and the infinite life design method is often used to avoid the challenge of precise component reliability design.

In terms of electricity consumption, the operating efficiency of ordinary crane motors is low, and the comprehensive energy consumption is significantly higher than that of European equipment. In terms of maintenance cycle and cost, European products’ hard toothed reducers, high-performance bearings, and specialized wheels have excellent durability and long maintenance cycles

The European single beam crane, with its compact structure, superior performance, and smooth operation, is suitable for high-precision machining workshops, warehouses and logistics centers with high automation, places with limited space, and places with high requirements for working environment, such as laboratories, hospitals, etc. It can meet the needs of efficient, precise, and stable lifting.

Ordinary single beam cranes, due to their simple structure and low cost, are suitable for small factories, workshop style enterprises, warehouses, freight yards, and other places with low requirements for lifting equipment and low operating frequency, as well as temporary lifting work sites such as construction sites and outdoor maintenance. They can meet the daily basic material handling needs.

Due to the adoption of advanced design concepts, high-quality raw materials, and advanced manufacturing processes, European single beam cranes have high manufacturing costs and purchase prices that are 30% -50% higher than ordinary single beam cranes. Ordinary single beam cranes have simple structures, relatively backward manufacturing processes, low manufacturing costs, and cheap procurement prices.

The European single beam crane has high operating efficiency, good reliability, low energy consumption, long maintenance cycle, and low cost. Although its components have high precision, high technical content, low failure rate, and controllable long-term use cost. The maintenance and repair cost of ordinary single beam cranes is low, due to their strong universality of components, cheap price, low maintenance technology requirements, and wider audience.

There are significant differences between European single beam cranes and ordinary single beam cranes in terms of design concepts, main beam structures, lifting mechanisms, operating drive and control systems, installation dimensions, safety and reliability, usage and maintenance costs, applicable scenarios, and costs. European cranes are characterized by precise calculations, high material utilization, and component level precision manufacturing, emphasizing comprehensive energy efficiency, long-term reliability, and space efficiency; Ordinary cranes occupy a certain market share due to their technological maturity and cost advantages, but there are gaps in efficiency, structural optimization, safety redundancy, and long-term maintenance.

There is no absolute superiority or inferiority between the two, and the choice should be based on specific job scenarios. When the frequency of use is high, the factory is limited, and long-term benefits are prioritized, European cranes are more valuable; When the short-term budget is decisive, temporary, or the operating conditions are simple, ordinary single beams are feasible options. Enterprises should have a clear understanding of equipment differences, comprehensively consider factors such as production demand, operating environment, and budget, and make scientific and reasonable investment decisions to improve production efficiency, reduce costs, and ensure operational safety.

For more information, feel free to contact us! We are happy to provide advice and tailor solutions for you!

We have 34 years of manufacturing experience and 12 years of export experience,business covers over 100 countries and regions worldwide, including Asia, Europe, America, Africa, and Oceania, forming a global product sales network.Received ISO system certification and CE product certification!

Our main products include 6 series of nearly 100 varieties, including electric hoists, electric winches, gantry cranes, bridge cranes, marine cranes, and gantry cranes.

E-mail: karida@weiyinglift.com

Website: www.wycrane.com