A MH5T-6M fully enclosed gantry crane was shipped to Thailand in 2022.

The following is an introduction to the model configuration of this gantry crane and the structure of its components.

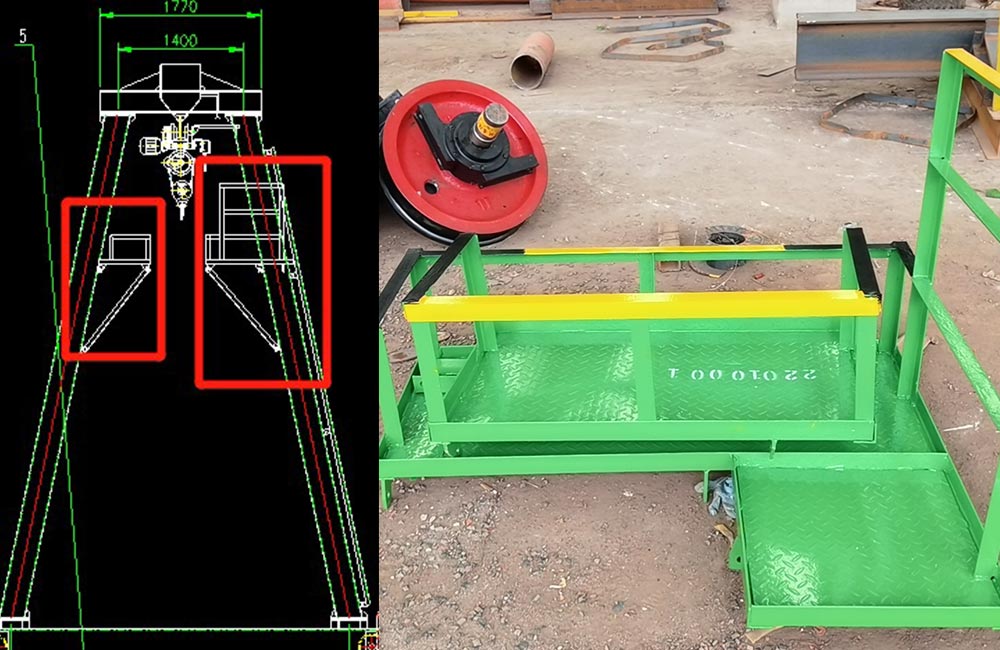

MH5T-6M full box, lifting 5 tons, span 6 meters, no external suspension, lifting 6 meters, voltage 220V50HZ 3 phase.

A. Large car Chongling soft start 0.8KW*2.

B. Vertical variable speed. Motor above the inner measuring ground beam, easy to run and save space.

C. Chint electrical appliances.

D.Power supply: four-stage seamless collector.

E. Big wheel: 300 wheels and 70 wheel slots.

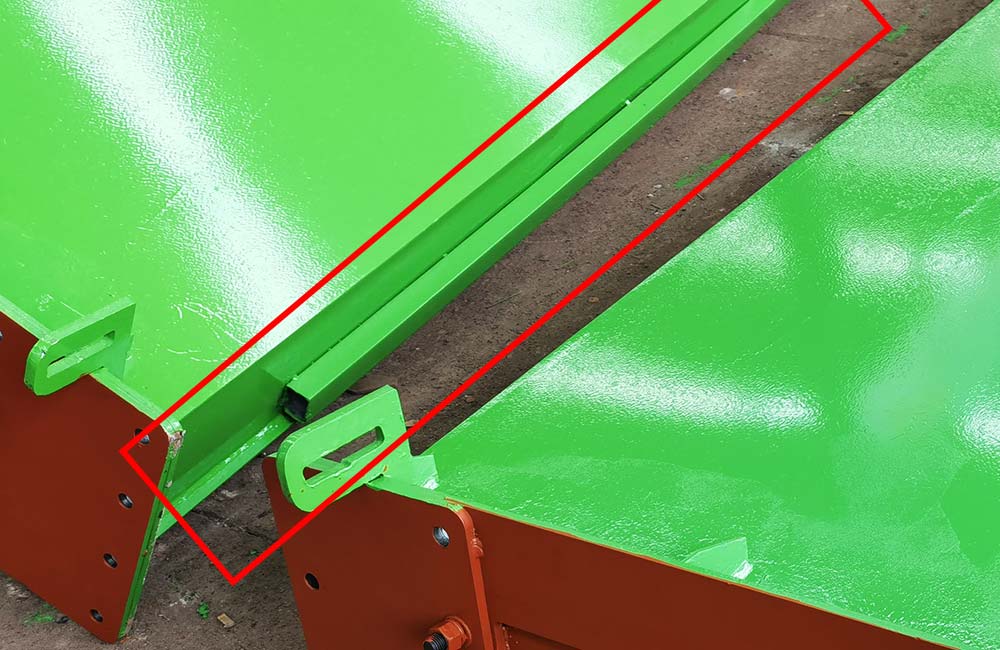

F. Sliding Cable Of Angle Steel, flat cable.

G. Running speed 20M/Min.

H. Control voltage: 36V, ground operation.

E-mail, telephone, tonnage, company name, signage.

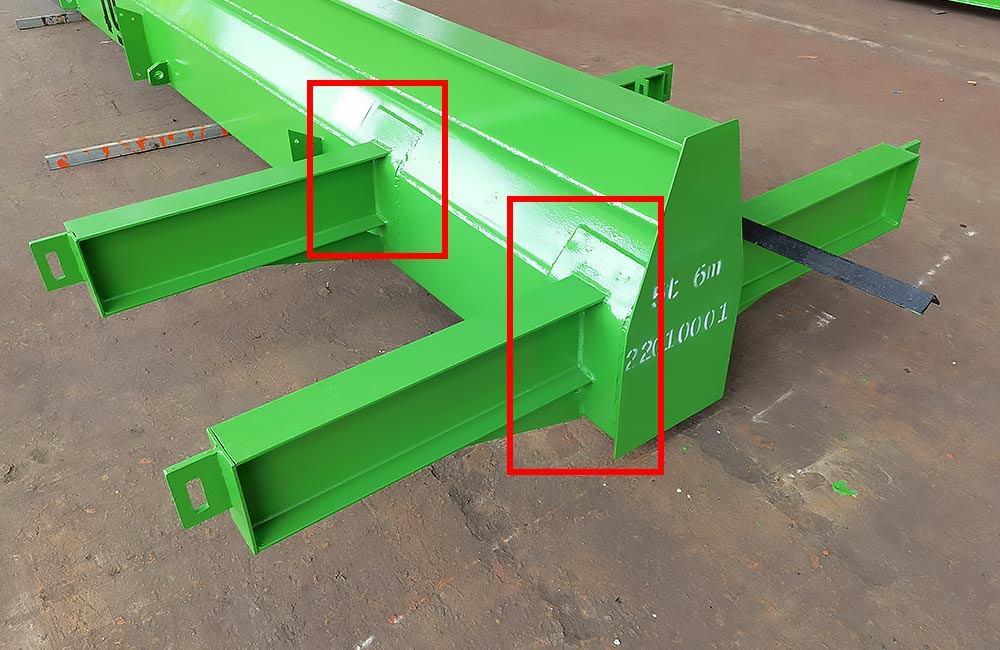

Reinforced plate at the cross-stretcher, more solid.

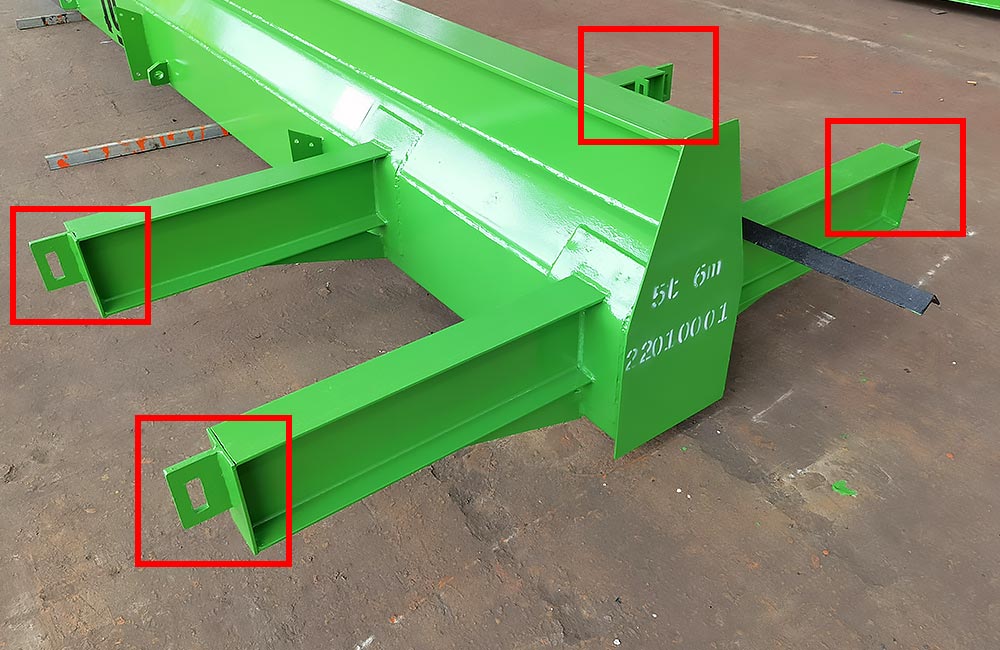

Connecting hole, connect with leg at ground level during installation, fix it with screws, and then lift it upwards. After lifting up, it has to be welded.

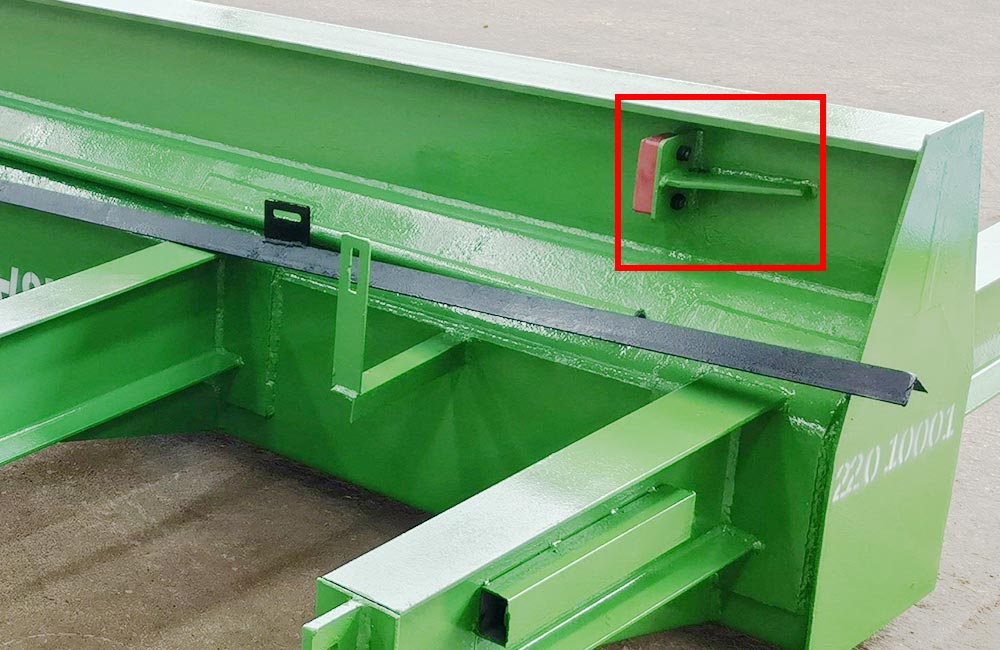

The end position of the main beam has a connecting plate on both sides, which is designed to install a rainproof cover and cannot be moved.

When the machine does not work on rainy days, the electric hoist needs to be moved under the rainproof cover to protect the hoist. The rainproof cover is assembled by two parts.

There are bumpers at both ends of the main beam, both on the same side.

Sliding Cable Of Angle Steel and cable conduit. Sliding Cable Of Angle Steel needs to be fixed with screws after arriving the site.

Each product has its own number, which is convenient for later tracking, and the corresponding two connectors have the same number for easy installation.

The connection hole corresponding to the main beam.

Two legs need to be welded with climb ladders to facilitate later installation and maintenance.

The maintenance countertop needs to be installed on two of the legs. When the electric hoist needs regular maintenance in the later stage, the personnel run the hoist to the countertop and climb the ladder to there for maintenance.

There is a conduit on one leg to power the electric hoist.

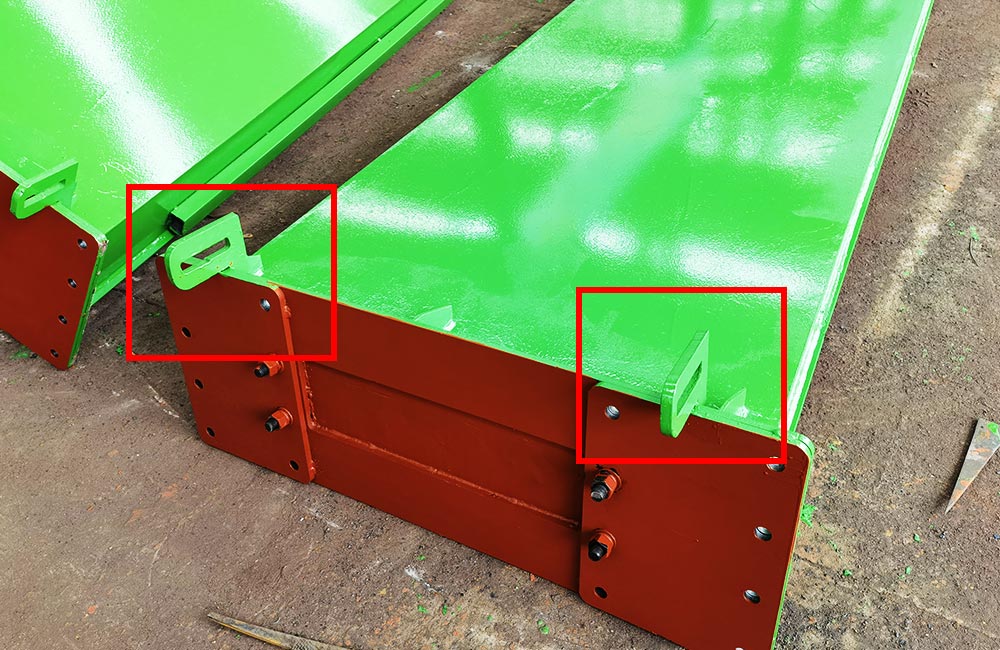

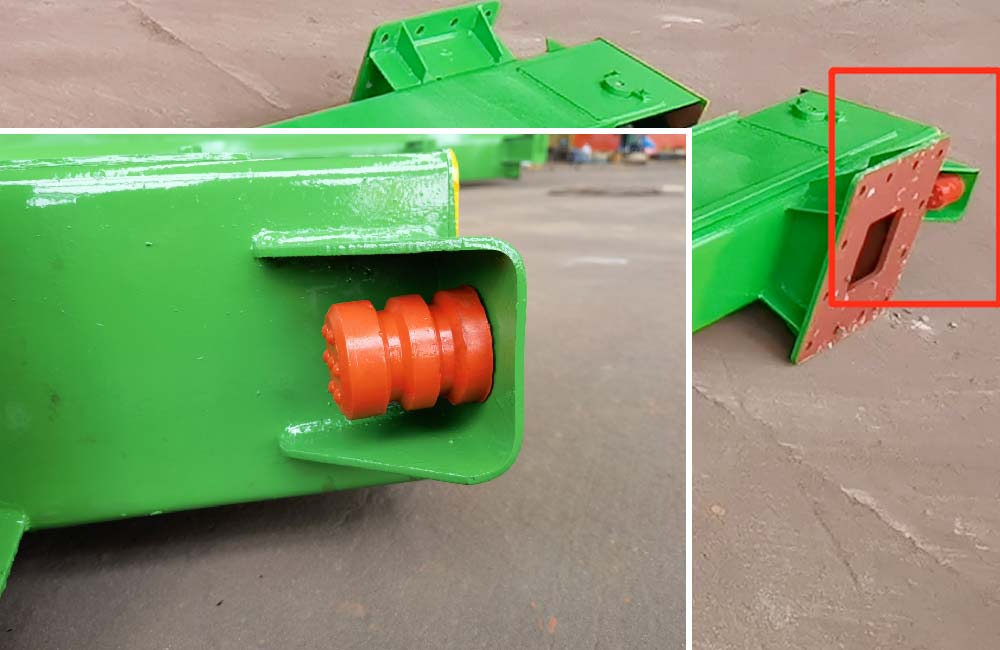

There is an anti-collision device at one end of the ground beam, which is unloaded and installed on the outside after arriving at the site.

There is an anti-derailment at one end of the ground beam and an anti-collision device on the anti-derailment, which also needs to be reversed.

Conduit.

The running length of the cable is 80 meters. Either spring or electric is fine. It is equipped with a 95-meter line. Because it has to be pulled, it takes a steel wire. The round cable is convenient for reeling.

Paint will fall off during installation. The customer needs to repaint after installation. The paint is usually placed in a wooden box with an electric motor and a transmission.